45K+S2X1.2F 2L Automatic Extrusion Blow Molding Machine

Introduction

45K+S2X1.2F automatic extrusion blow molding machine is with two mould stations. It is specialized in forming bottles whose maximum volume is 2 L. Take the detergent bottle which is 800 ml and 40 g for example, a 45K+S2X1.2F machine can blow mould 270 this kinds of bottles each hour, 6480 per day, and 2.26 million every year.

General Features

- 1. The screw diameter is 45 mm. Maximum mould available for 45K+S2X1.2F automatic extrusion blow molding machine is with maximum volume of 2L.

- 2. Siemens PLC system and human-machine interface are adopted in its electric system.

- 3. Its hydraulic system employs exported Yuken hydraulic valves and pumps from Japan.

- 4. Plasticizing system features high efficiency and less energy consumption.

- 5. Invertor and harden surface gear box are used in the extruding system.

- 6. Single hydraulic cylinder used for parison injection is of highly synchronization.

- 7. 45K+S2X1.2F automatic extrusion blow molding machine features convenient mold changing due to adoption of adjustable extruding cover and hydraulically driven mould head.

- 8. With center locking clamping mechanism, the clamping system is characterized with long-term clamping force.

Technical Data of 45K+S2X1.2F 2L Automatic Extrusion Blow Molding Machine

1. General Features

| Carriage Horizontal Shuttle Stroke | mm | 400 |

| Dry Cycle | sec | 4' |

| Clamp Force | kN | 30 |

Pressure of Hydraulic System |

Mpa |

16 |

Pressure of Pneumatic System |

Mpa |

0.6-0.8 |

Pressure of Cooling System |

Mpa |

0.2-0.3 |

| Air Consumption (Estimated) | m3 / hr | 5 |

| Minimum Pressure for Cooling Water to Machine | Mpa | 0.2 |

| Power of Pump Motor for Hydraulic Movements | kW | 5.5 |

| Power of Servo Pump Motor (if Needed) | kW | (5.5) |

| Power of Die Head Heating | kW | 3 |

| Power of Knife | kW | 2 |

| Total Power Installed (Estimated, Maximum) | kW | 22.5(28) |

2. Extruders

| Screw Diameter | mm | 45 |

| Extruder Rotating Speed | / | 20~60 |

| Power of Electric Motor | kW | 5.5 |

| Power of Barrel Heating | kW | 4.5 |

| Max. Throughput = PE | kg/h | 20 |

| Max. Throughput = PP | kg/h | 14 |

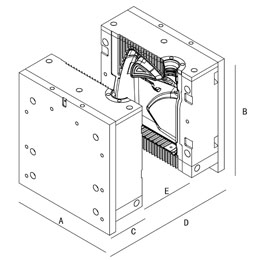

3. Mould Dimensions

| Maximum Width | A | mm | 250 |  |

| Maximum Length | B | mm | 300 | |

| Minimum Depth | C | mm | 115 | |

| Clamp Open Max. Daylight | D | mm | 330 | |

| Open Stroke | E | mm | 130 | |

| Max Weight of Mould | kg | 100 |

4. Production Possibilities

| Cavities | 1 | |

| Max. Center Distance | mm | / |

| Max. Container Width | mm | 280 |

| Max. Container Height | mm | 30 |

| Max. Container Depth | mm | 40 |

| Container Capacity (Estimated) | lt | 2 |

5. Machine Dimensions

| Maximum Width | mm | 1930 |

| Maximum Length | mm | 3130 |

| Maximum Height | mm | 2100 |

| Total Weight | kg | 4000 |

As one of the leading bottle blowing machine suppliers in China, Lanteky not only produces high quality machineries but also provides considerate services for clients. We provide one year equipment warranty to each 45K+S2X1.2F automatic extrusion blow molding machine. During the warranty period, damaged machine parts, not including the quick wear parts, can be changed into new ones without charging fees for buying them. Apart from this, we can install this machine for free for domestic clients, and all-life service is offered to our clients all over the world.

English

English Português

Português Français

Français